Description

ZN28+-12 Indoor AC high voltage vacuum circuit breaker is switch equipment of three-phase, 50Hz, rated voltage 12KV, as the protective and control unit for other power equipment. This vacuum circuit breaker can be switched frequently.

Product introduction and application

ZN28+-12 Indoor AC high voltage vacut1m circuit breaker is indoor switch equipment of three-phase,AC50Hz, 12KV, used as protective and control unit in power system of mineral enterprises, suitable for switching on/off different loads and frequent operation, breaking short circuit current for many times. The breaker body integrated with operating mechanism, vacuum interrupter is laid rear and operating mechanism assembled in the front, easy to be mounted without adjustment and little maintenance required. It provides complete, reliable mechanical and electrical interlock system.

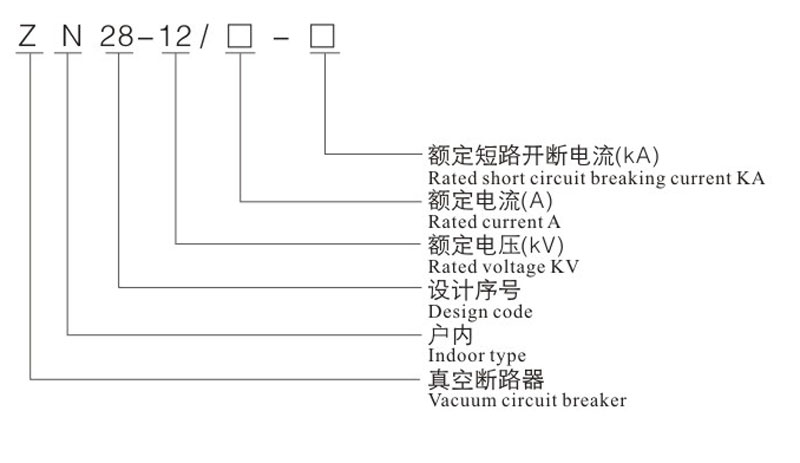

Model and meaning

Applicable standards

The breaker complies with GB 1984-2003 "High voltage AC Circuit breakers",JB3855-1996 "3.6-40.5KV Indoor AC high voltage vacuum circuit breaker IEC 56 standard

It can be interchangeable between ZN65, ZN12, ZN28 model circuit breakers.

Working conditions

a.Ambient humidity

Daily average not more than 95%

Monthly average not more than 90%

Daily vapor pressure ≤2.2 x 10.3MPA

Monthly vapor pressure ≤1.8 x 10.3MPA

b.Ambient temperature

Highest temperature: 40℃

Lowest temperature: -15℃

c.Altitude not more than 1000m

d.Earthquake not over grade 8

e.The working site shall have no water drop, no flammable or explosive danger, no corrosive gas and severe vibration.

f.Any special requirement, please advise and negotiate during ordering products.

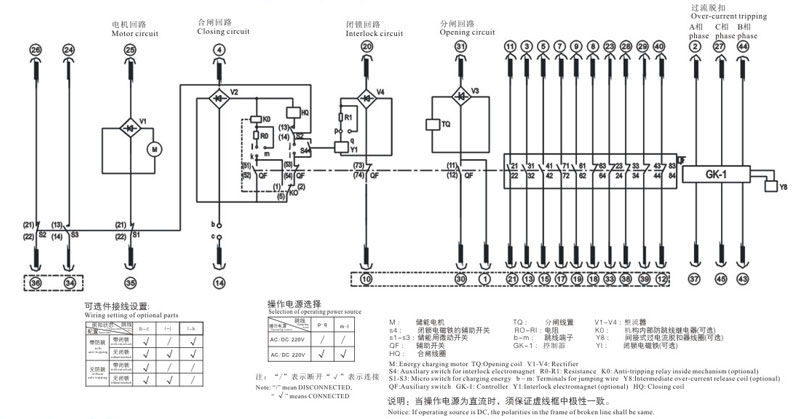

Interior wiring theory

The breaker body and operating mechanism laid in the back and front, assembled together, this structure can reduce unnecessary parts and make better coordination and operating performance between mechanism and vacuum interrupter, lessen the operating noise and power loss, user can put into operation without need of adjustment.

The breaker adopted middle sealed and connected type lengthways magnetic field vacuum interrupter, main shaft, opening spring and oil buffer and etc parts assembled inside the frame, the bottom of frame provide mounting holes for fixing breaker. 6 insulators fixed in the back (upside and downside 3pcs), upper insulators fixed the moving support, downside insulators fixed with static support, the rear of moving and static supports used as outgoing terminals. Vacuum interrupter laid between moving and static supports, main shaft connected with vacuum interrupter via insulating pulling rod, bent arm, there has two insulating rod between moving and static supports 10 reinforce the strength

The breaker adopted vacuum interrupter with high vacuum degree. When moving and static contacts driven by operating mechanism to switch off the line with load, there will produce vacuum arc between contacts, and it will produce some lengthways magnetic field due to special configuration of the contacts, which will keep vacuum arc being extended and remain low arcing voltage. When current passing zero, the residual ion, electrons and metal steam will recombine or condense on the surface of contact or shield cover within microseconds, the dielectric strength cross isolating break will recover quickly, therefore electric arc is extinguished. Lengthways magnetic field controlling vacuum arc will get high and steady breaking capacity.

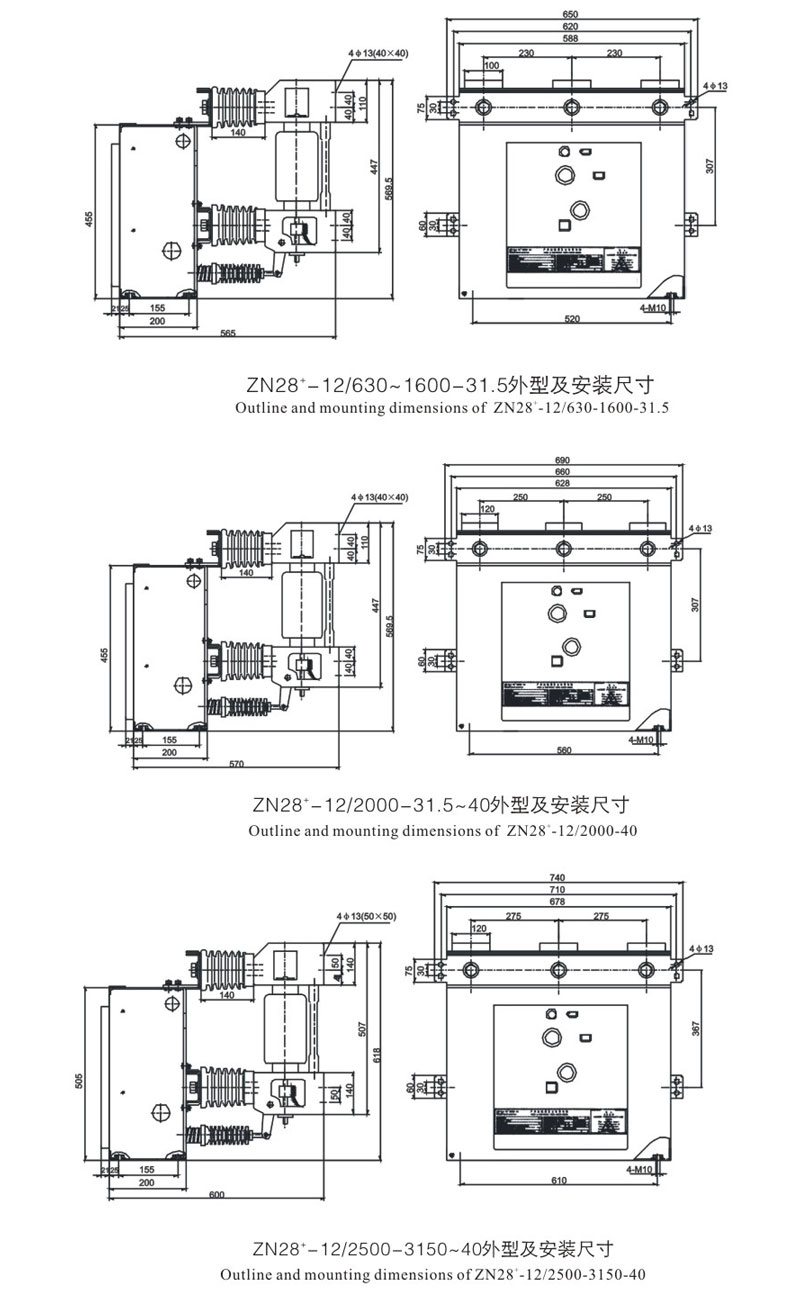

Outline and mounting dimensions

Interior working theory diagram

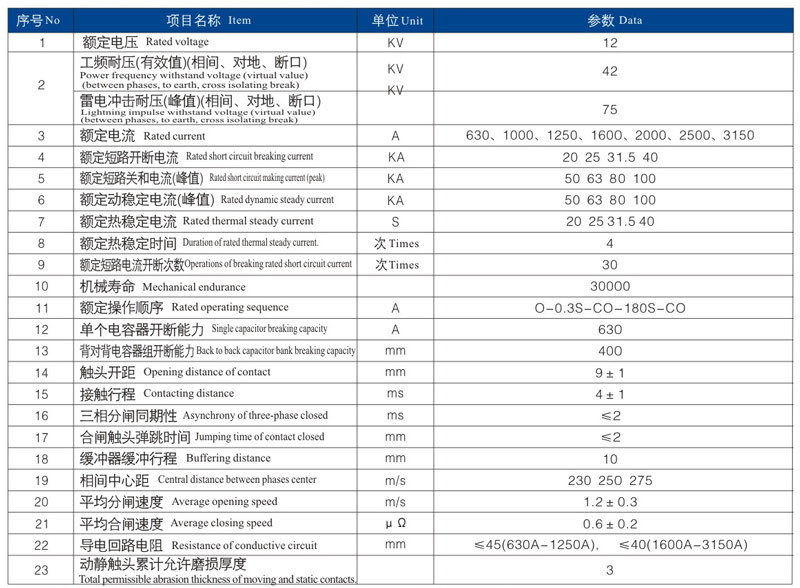

Main technical parameters

Notes: if special requirement specified, please contact with our company